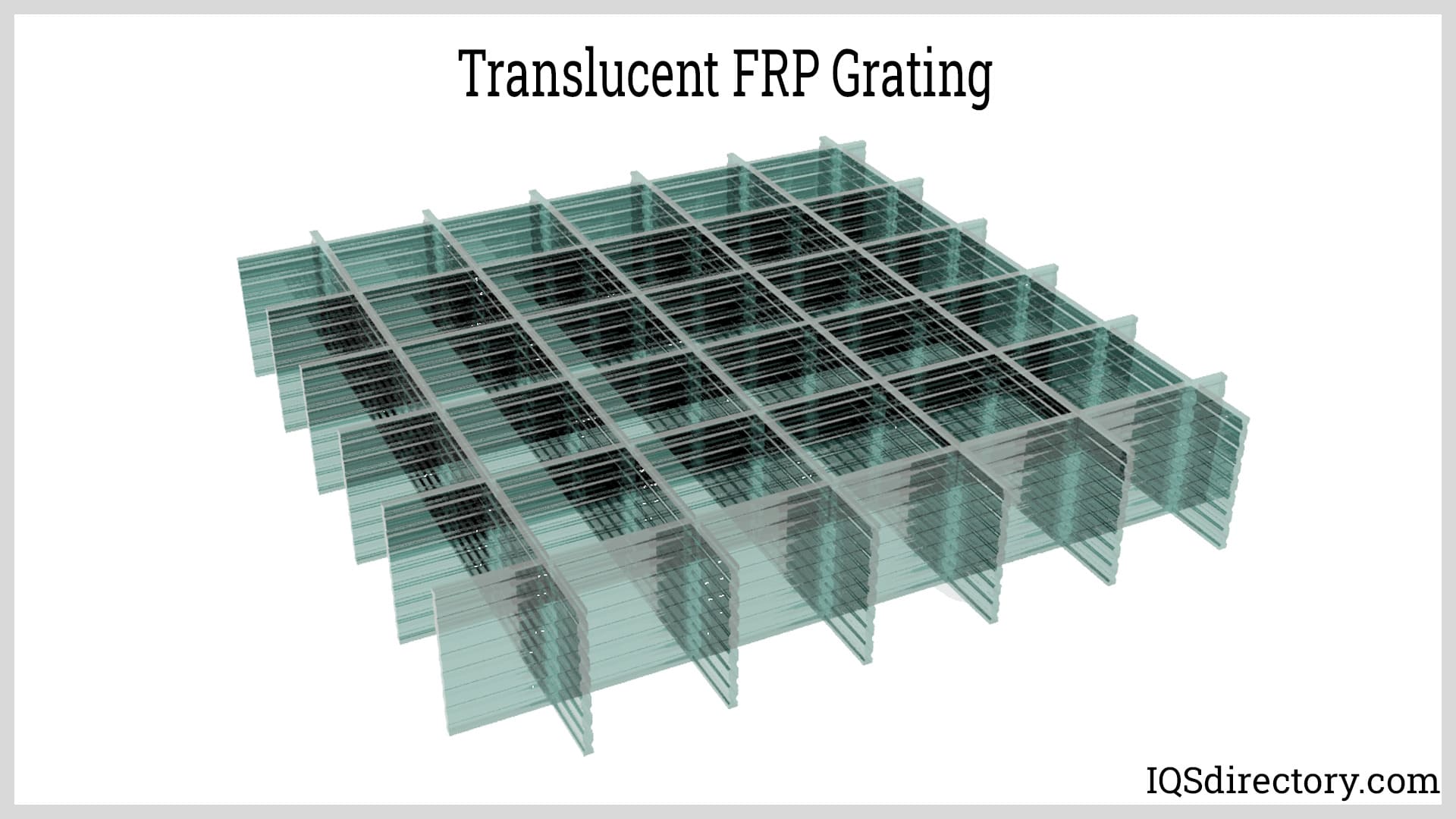

These grids block the passage of some debris and light, while remaining somewhat permeable to air and often liquids. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Strongwell is the world's leading pultruder of FRP structural components. Strongwell’s products include structural shapes, plate, fiberglass grating, building panels, handrail systems, ladder & cage systems, bridge decks, cooling tower components, planking systems, and custom shapes. If you would like more information about our company then please let us know!

Indiana is the benchmark other manufacturers strive to achieve. This financially strong, family owned company with over 35,000 sq. ft. of manufacturing area offers cost-effective, quality structural, decorative products, including precision crafted light & heavy duty welded gratings. Operating in accordance with NAAMM standards, Indiana has built its reputation on "personal service".

At Ryan Herco Flow Solutions, we take pride in delivering durable and reliable floor gratings designed to meet the highest standards of performance and safety. We understand the critical role that flooring systems play in industrial and commercial environments, and we engineer our floor gratings to provide strength, stability, and long-lasting value.

More Stainless Steel Grate Manufacturers

Used for drainage, support, filtration, partition and enclosure formation, steel grates are employed in many different environments and may be made of a number of different materials. The beneficial attributes of stainless steel, however, make it a popular choice for grate construction. As indicated in the name, this steel alloy does not rust, corrode or stain easily.

This allows its use in a variety of industrial applications involving volatile or corrosive fluids and gases. Additionally, stainless steel is known for its high tensile strength and durability. These properties and others make this material a popular choice from many industrial, commercial and even residential grates which may be high demand applications.

Food processing and preparation, chemical processing, industrial flooring, oil and gas producers, metal and mining facilities, pulp and paper plants as well as shipbuilding industries make frequent use of these metal grates. Outdoor drainage and non-slip surfaces such as ramps, stairs, docks, catwalks and footbridges also utilize this resilient material for necessary grating.

An aesthetically pleasing metal, stainless steel grates can be both functional and decorative elements utilized in traditional grate formations such as I-bar, rectangular bar and plank as well as intricate designer arrangements.

Steel is one of the most common alloys in use today. Made predominantly of iron and varying amounts of carbon, steel alloys include a wide variety of additional metallic components. Chromium is an essential ingredient in the creation of stainless steel. Grates made of this material have a formula that consists of at least 10% chromium and this element is responsible for the extreme resistance to wear and corrosion of stainless steel.

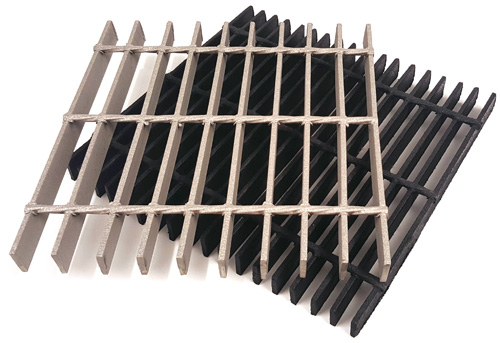

The first step in creating stainless steel grates is to mix and melt or sinter metal powders together and cast them into stock shapes. These rods, sheets and bars are then further processed to create the grid and mesh of a grate. Expansion grating and bar grating are the most popular techniques used to manufacture stainless steel grates. Expansion metal is created by perforating a steel sheet and stretching it to form diamond-shaped openings.

Bar grating joins steel rods together through welding, swaging, pressure-locking or riveting, creating a high-strength, load bearing grate. The process used for a specific grate depends largely on the intended use and specifications required of it. Serration or non-slip coatings are often utilized for floor gratings made of stainless steel to add traction.

While finishing is an important factor in manufacturing grates, additional considerations include the size, shape and density of the holes or gaps in a given grate as well as connection size.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services