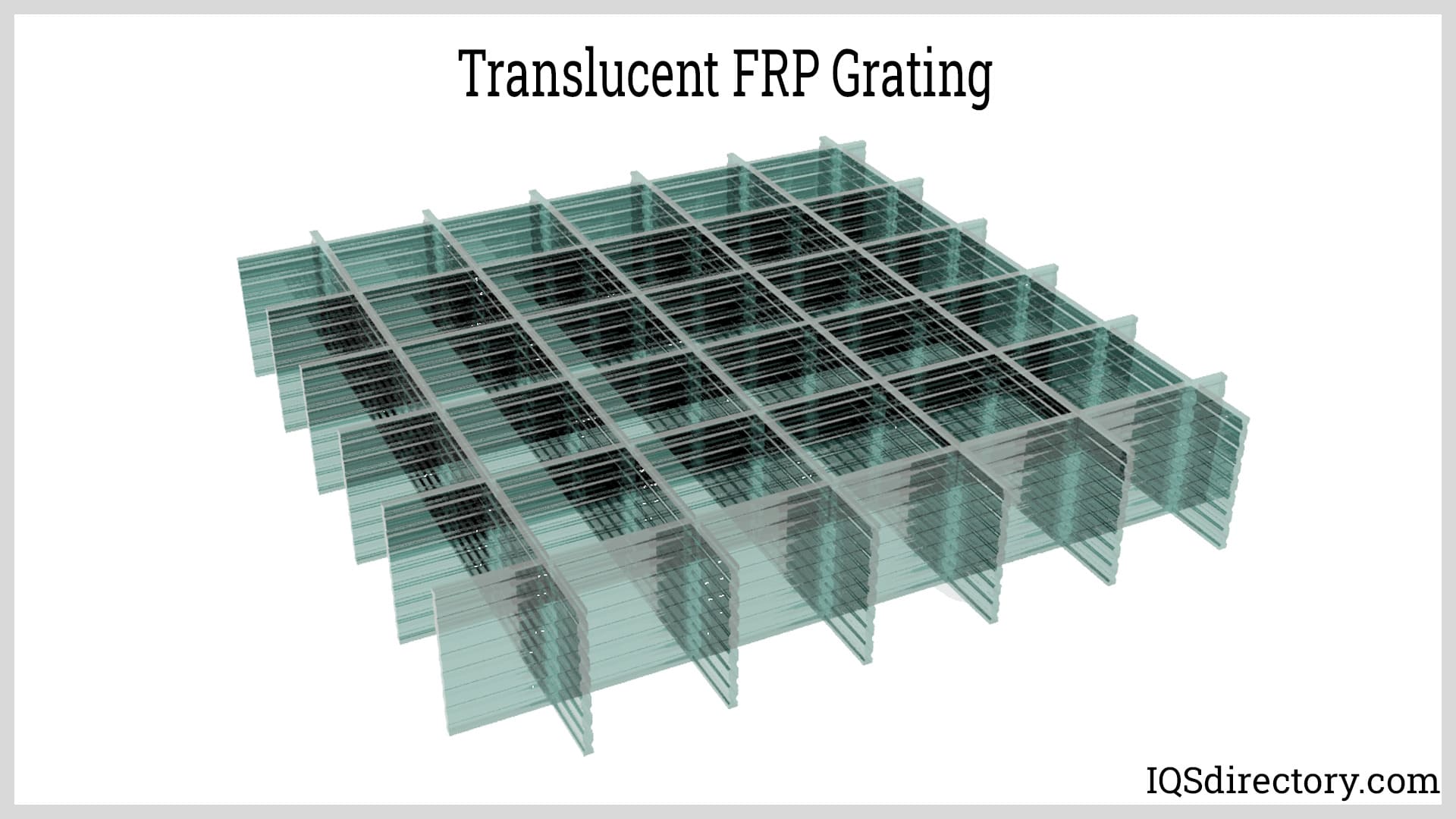

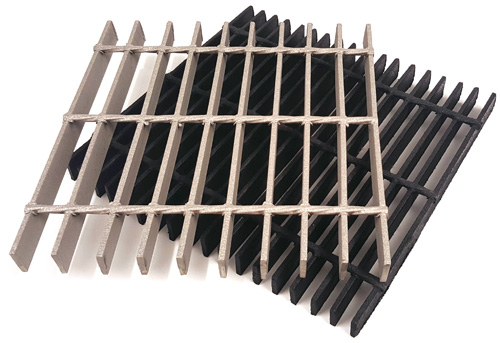

These grates block the passage of some debris and light, while remaining somewhat permeable to air and liquids. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Strongwell is the world's leading pultruder of FRP structural components. Strongwell’s products include structural shapes, plate, fiberglass grating, building panels, handrail systems, ladder & cage systems, bridge decks, cooling tower components, planking systems, and custom shapes. If you would like more information about our company then please let us know!

Indiana is the benchmark other manufacturers strive to achieve. This financially strong, family owned company with over 35,000 sq. ft. of manufacturing area offers cost-effective, quality structural, decorative products, including precision crafted light & heavy duty welded gratings. Operating in accordance with NAAMM standards, Indiana has built its reputation on "personal service".

At Ryan Herco Flow Solutions, we take pride in delivering durable and reliable floor gratings designed to meet the highest standards of performance and safety. We understand the critical role that flooring systems play in industrial and commercial environments, and we engineer our floor gratings to provide strength, stability, and long-lasting value.

More Galvanized Grating Manufacturers

Used for drainage, support, filtration, partition and enclosure formation, gratings are employed in many different environments and may be made of a number of different materials. Common metal grate materials that are pre-treated through galvanization include iron, steel and aluminum.

Though these grates may be used without galvanization, this protective process improves the working lifespan of a grate in industries such as heating and cooling, refrigeration, architecture, power generation, automotive, walkway construction, marine superstructure, petrochemical processing, sewage treatment and waste management.

The materials moving through these grate systems are often highly corrosive to even durable materials such as steel. Zinc galvanization provides an added layer of protection. While this layer, varying in thickness from 1mm to just over 4mm, will eventually corrode, the damage caused by corrosion is significantly slowed.

The application of zinc is a relatively simple and cost effective procedure making its use popular for a variety of metal grating fixtures such as grills, grids, grip plates and grates, stair treads and drain grates.

Galvanization is most commonly achieved through a process known as hot-dip galvanizing. Essentially, this involves bathing iron or steel grates or grate components in molten zinc. Zinc is kept liquefied at temperatures near 860 degrees F.

The metal articles, first cleaned with a light acid solution, are either dipped or fed into the zinc bath which forms a metallurgical bond with the substrate materials. When exposed to oxygen and carbon dioxide in the atmosphere, the zinc is cured and forms a layer of zinc carbonate that further protects the bars, mesh and sheets of iron, aluminum or steel grates.

While traditional hot-dipping is still widely used, two additional techniques are growing in use and popularity. Electro-galvanizing passes an electric current through the zinc compound in order to create a thinner and more tightly bonded coating.

The newest development is the environmentally friendly thermal diffusion galvanizing which eliminates the hazardous caustic and acid baths used in traditional methods. Rather than a molten bath, zinc powder is applied to grate components which are then sealed in a drum and processed through a rotary oven.

Each technique produces spangle, either uniform or large grain, on the finished grate. Spangle is the appearance of a crystalline structure that gives the formerly shiny metals a dull grey appearance.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services