Grates are a framework of metal or fiber reinforced plastic bars and sheets that are perforated or otherwise slotted to create a grid. In flooring applications, metal grates or plastic grating offers several advantages over solid surfaces. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Strongwell is the world's leading pultruder of FRP structural components. Strongwell’s products include structural shapes, plate, fiberglass grating, building panels, handrail systems, ladder & cage systems, bridge decks, cooling tower components, planking systems, and custom shapes. If you would like more information about our company then please let us know!

Indiana is the benchmark other manufacturers strive to achieve. This financially strong, family owned company with over 35,000 sq. ft. of manufacturing area offers cost-effective, quality structural, decorative products, including precision crafted light & heavy duty welded gratings. Operating in accordance with NAAMM standards, Indiana has built its reputation on "personal service".

At Ryan Herco Flow Solutions, we take pride in delivering durable and reliable floor gratings designed to meet the highest standards of performance and safety. We understand the critical role that flooring systems play in industrial and commercial environments, and we engineer our floor gratings to provide strength, stability, and long-lasting value.

More Floor Grating Manufacturers

Floor Gratings: Comprehensive Guide to Types, Applications, and Benefits

Floor gratings are essential components in modern industrial, commercial, and municipal infrastructure, offering critical solutions for slip resistance, drainage, and ventilation across a diverse range of environments. Whether you manage a manufacturing facility, design public spaces, or oversee maintenance for high-traffic walkways, understanding the nuances of industrial floor grating systems will help you make informed decisions that optimize safety, performance, and cost-efficiency.

What are Floor Gratings and Why Are They Important?

Floor gratings are engineered coverings featuring a grid or mesh structure, typically composed of metal or reinforced plastic, designed to create a secure, textured surface. This construction significantly enhances slip resistance, reducing the risk of workplace injuries and accidents due to falls. In high-traffic environments prone to wet conditions or oil spills, drain grates in floors further mitigate hazards by allowing the efficient passage of liquids and debris such as water, oil, and particulate matter.

These grates are fundamental for promoting occupational safety, maintaining compliance with regulatory standards (such as OSHA or local building codes), and supporting the longevity of flooring in demanding settings. The design of floor gratings also contributes to improved ventilation, sound transmission, and lighting—key considerations in industrial and commercial architectural planning.

Key Applications of Floor Gratings

Wondering where floor gratings are most commonly used? Their versatility and robust design make them indispensable across numerous sectors. Popular industries and environments that utilize floor grates include:

- Manufacturing plants and assembly lines

- Warehouses and distribution centers

- Power generation and utility facilities

- Oil, gas, and petrochemical processing plants

- Food and beverage processing facilities

- Mining and metallurgy operations

- Pulp and paper manufacturing

- Commercial kitchens and food prep areas

- Public infrastructure such as bridges, docks, city streets, and sidewalks

- Commercial and residential drainage systems

- Refrigeration and cold storage rooms

- HVAC and mechanical service walkways

- Pedestrian walkways and stair treads

In outdoor applications, such as bridges, sidewalks, and piers, floor gratings are often selected for their superior drainage capacity and traction enhancement. In these cases, the grating typically serves as the primary walking surface, allowing rainwater or snowmelt to drain away efficiently, minimizing puddling and ice formation.

Are you evaluating floor grating for a specific project? Contact us or browse our drain grating manufacturer directory to compare options and request quotes tailored to your application.

How Floor Gratings Improve Safety and Efficiency

Safety is a paramount concern in any environment where slip, trip, and fall hazards exist. Floor gratings are engineered to address these risks by:

- Providing excellent traction in wet, oily, or debris-laden conditions

- Allowing for rapid drainage of liquids and particulate matter

- Reducing the accumulation of hazardous substances on walking surfaces

- Enhancing visibility and ventilation, contributing to a more comfortable workspace

- Complying with industry safety regulations and standards

Looking for tips on choosing the safest floor grating? Consider factors such as bar spacing, surface texture, load-bearing capacity, and corrosion resistance based on your specific environment.

Types of Floor Gratings: Materials and Manufacturing Processes

Floor gratings are manufactured from a variety of materials, each offering unique advantages for different use cases. The main categories include:

1. Metal Gratings

Metal floor gratings are highly durable and suitable for heavy-duty and industrial applications. Common metals used include:

- Stainless Steel Grating: Ideal for corrosive or wet environments due to its exceptional resistance to rust and chemical attacks. Frequently used in food processing, chemical plants, and outdoor installations.

- Mild Steel (Carbon Steel) Grating: Cost-effective and strong, making it a popular choice for general industrial flooring and platforms.

- Galvanized Steel Grating: Steel grating coated with zinc to enhance corrosion resistance, widely used in wastewater treatment plants and outdoor walkways.

- Aluminum Grating: Lightweight, non-magnetic, and resistant to corrosion, making it suitable for environments where weight savings and easy handling are priorities. Learn more about aluminum grating options.

- Iron and Brass Gratings: Used in architectural and decorative applications as well as in areas requiring specific material properties.

Key manufacturing methods for metal grates include:

- Expanded Metal Grating: Produced by slitting and stretching metal sheets to create a mesh with diamond-shaped openings. This method generates minimal waste and offers excellent strength-to-weight ratios.

- Punched/Perforated Metal Grating: Created by using punch presses to produce precise hole patterns in metal sheets. Suitable for applications requiring specific drainage or ventilation characteristics.

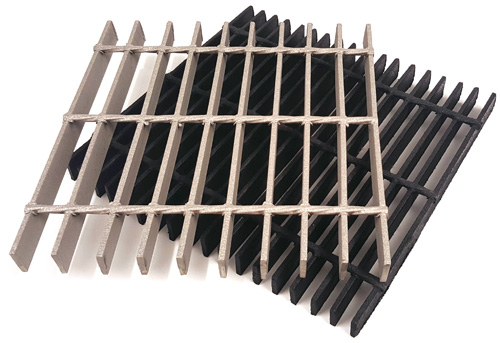

- Welded Bar Grating: Comprises load-bearing bars joined to cross bars at regular intervals, providing superior load-bearing capacity and stability for walkways, catwalks, and mezzanine floors.

- Press-Locked Grating: Assembled by pressing crossbars into notched bearing bars under high pressure, resulting in a rigid, durable structure.

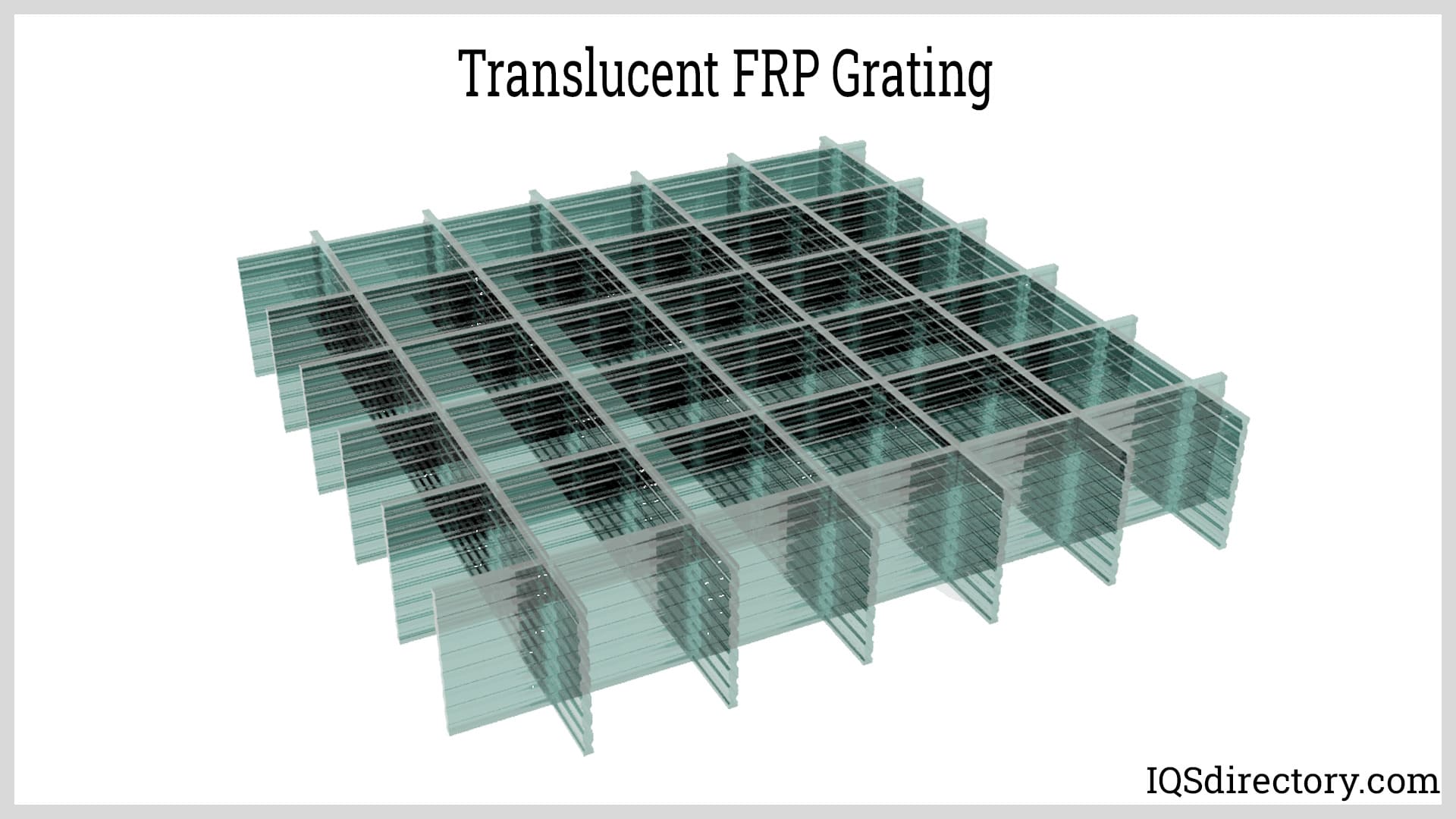

2. Fiberglass Reinforced Plastic (FRP) Gratings

FRP floor gratings are manufactured by weaving continuous fiberglass strands through thermosetting resins (such as polyester or vinyl ester), then curing the composite to form sturdy, corrosion-resistant panels. Advantages of FRP gratings include:

- Excellent resistance to chemicals, acids, and moisture

- Lightweight and easy to install or relocate

- Non-conductive and spark-resistant, making them ideal for electrical, marine, and hazardous environments

- Low maintenance and long service life

- Available in molded or pultruded forms, offering flexibility for custom applications

Need help comparing metal vs. fiberglass grating? Explore our in-depth guides or reach out to our experts for tailored recommendations based on your environmental and structural needs.

Design Considerations for Selecting Floor Grating

Choosing the right floor grating system involves evaluating several key factors:

- Load-Bearing Capacity: Assess the maximum expected weight—foot traffic, vehicles, equipment—to select the appropriate bar thickness and spacing.

- Bar and Mesh Spacing: The size and configuration of openings determine what can pass through (e.g., water, debris) and influence drainage, safety, and visibility.

- Slip Resistance: Surface textures such as serrated bars or grit coatings enhance grip in wet or oily environments.

- Corrosion and Chemical Resistance: Select materials and coatings according to exposure to moisture, chemicals, or harsh conditions.

- Ease of Installation and Maintenance: Consider modular designs, removable panels, and ease of cleaning for ongoing facility management.

- Compliance with Standards: Ensure the grating meets local codes (e.g., ADA accessibility, OSHA requirements) for safety and accessibility.

Have questions about grating specifications? Use our product selection tool to filter grating options by material, load capacity, size, finish, and more.

Benefits of Floor Gratings: Why Specify Them in Your Project?

The widespread use of floor grating is a testament to its value in facility design and operations. Some of the most compelling benefits include:

- Enhanced Safety: Reduced risk of slips, trips, and falls; improved drainage and traction; compliance with safety standards.

- Durability and Longevity: Robust materials withstand heavy loads, corrosive environments, and prolonged exposure to the elements.

- Maintenance Efficiency: Easy to clean and maintain; minimizes downtime and lowers lifecycle costs.

- Versatility: Suitable for virtually any environment—industrial, commercial, municipal, or residential.

- Customization: Available in a wide range of materials, sizes, finishes, and profiles to meet project-specific requirements.

- Sustainability: Many gratings are manufactured from recyclable materials and support green building initiatives.

Curious about the cost vs. benefit analysis of different grating types? Our resource center provides detailed comparisons to help you maximize ROI on your flooring investment.

Common Use Cases and Industry Applications

Whether you need to specify grating for a refinery catwalk, a wastewater treatment plant, or a municipal sidewalk, the correct choice will depend on your operational environment, load requirements, and exposure to chemicals or the elements. Some typical use cases include:

- Industrial Walkways and Platforms: Ensure worker safety and efficient movement in factories, refineries, and plants.

- Drainage Trench Covers and Sump Grates: Prevent flooding and debris accumulation in commercial, municipal, and residential settings.

- Stair Treads and Landings: Provide slip-resistant surfaces for stairways in industrial, commercial, and public buildings.

- Docks, Marinas, and Bridges: Deliver long-lasting performance in marine and outdoor environments where water drainage and corrosion resistance are critical.

- ADA Compliant Gratings: Allow for wheelchair access and safe passage for all users in public infrastructure.

- Machine Guarding and Equipment Protection: Shield sensitive equipment or hazardous areas while allowing airflow and visibility.

Need inspiration for your next project? Browse our case studies to see how leading companies have deployed floor gratings to solve complex safety, drainage, and durability challenges.

Installation and Maintenance Best Practices

Proper installation and maintenance are crucial to maximizing the service life of your floor grating system. Here are some best practices:

- Ensure substructure is properly prepared and level before installation

- Follow manufacturer guidelines for anchoring and fastening grates

- Allow for expansion and contraction, especially with metal and FRP gratings

- Regularly inspect for signs of damage, corrosion, or excessive wear

- Clean grates periodically to remove debris and maintain slip resistance

Looking for detailed installation guides and maintenance checklists? Access our technical library for downloadable resources and troubleshooting tips.

How to Choose the Right Floor Grating Supplier or Manufacturer

Selecting a reputable floor grating manufacturer is key to ensuring you receive high-quality products that meet your project’s technical requirements and budget. When evaluating suppliers, consider:

- Product range and customization capabilities

- Certifications and compliance with industry standards

- Technical support, engineering assistance, and lead times

- Warranty and after-sales service

- References and track record in your industry

Ready to request a quote or compare suppliers? Visit our floor grating supplier directory for a curated list of trusted manufacturers and distributors.

Frequently Asked Questions about Floor Gratings

- What is the difference between welded and press-locked grating?

Welded grating uses fusion welding to join cross bars to bearing bars at each intersection, resulting in the strongest and most rigid structure. Press-locked grating relies on mechanical pressure to interlock bars, providing a smooth, clean appearance without welding marks. - How do I determine the correct grating for chemical exposure?

Select materials such as stainless steel or FRP with appropriate resin systems (e.g., vinyl ester) for maximum resistance to specific chemicals encountered in your application. - Are all floor gratings ADA compliant?

No, ADA compliance requires specific bar spacing and surface properties. Confirm grating meets accessibility requirements for public spaces. - Can floor gratings be used in architectural and decorative projects?

Absolutely. Architectural metal grating and custom designs are available for stairs, facades, sunshades, and more, offering both functional and aesthetic benefits. - How do I estimate the cost of floor grating for my project?

Cost is determined by material, size, load capacity, finish, and customization. Use our request a quote tool for fast, accurate pricing from multiple suppliers.

Explore More Floor Grating Solutions

As industry demands for safety, efficiency, and sustainability continue to grow, floor gratings remain at the forefront of facility design and maintenance strategies. From industrial flooring and drainage grates to architectural metal grating and fiberglass reinforced plastic (FRP) solutions, the market offers a wide spectrum of products engineered to meet even the most challenging requirements.

Want to learn more about innovative grating technologies, custom fabrication services, or project-specific recommendations? Connect with our network of manufacturers or explore our resource center for:

- Technical datasheets and CAD drawings

- Application guidelines by industry

- Installation videos and how-to guides

- Product selection calculators

- Regulatory compliance updates

Stay ahead of the curve—sign up for our industry newsletter for the latest trends, product launches, and expert insights on floor grating solutions.

For more information on drain grates, aluminum grating, and other specialized products, visit our comprehensive product pages or contact our technical team for personalized assistance.

Ready to start your project? Get a fast, free quote from leading floor grating manufacturers now.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services