More Floor Grating Manufacturers

Municipal and federal regulations often mandate the use of floor grating in walkways, industrial facilities, and commercial buildings—especially in areas where fluid leakage, spills, or environmental exposure may occur. Floor gratings offer secure and durable walking surfaces, ensuring workplace safety and compliance with building codes and occupational safety standards.

In addition to their primary safety function, grating systems are frequently incorporated into ventilation applications to facilitate effective airflow within diverse structures, including factories, warehouses, and public spaces. Gratings can also serve as sunshades, provide structural support for handrails and balustrades, enhance architectural decor, or act as ornamental screens for both functional and aesthetic purposes. Their adaptability makes them a preferred choice for architects, engineers, and facility managers seeking solutions for drainage, ventilation, and access.

The History of Floor Gratings

Metal grates have been produced since the advent of metalworking, first appearing during the Bronze Age. An early example comes from the Italian city of Elea (later Velia), which was under Roman control by the 3rd century BC. There, metal grates served as street drainage systems, functioning as gutters.

By the 11th century, floor grates were being used in homes to hold coal at the bottom of fireplaces for heating. These early grates, primarily made from cast iron and steel, were more ornate than modern versions, which prioritize functionality. However, antique or antique-style grates are still sometimes requested for aesthetic purposes in restoration projects or classic architecture.

Floor grates have also played a pivotal role in urban infrastructure, particularly for sewage and stormwater drainage. James T. McHugh received a U.S. patent for a sewage grating in 1884, marking a significant milestone in the use of engineered grates for public health and sanitation. Today, manufacturers produce industrial floor grates for a wide range of applications—including commercial flooring, mechanical systems, and safety walkways—in addition to their traditional roles. This diversification is driven by advances in materials science, enabling the use of metals like stainless steel and aluminum, as well as non-metallic options such as fiberglass-reinforced plastics (FRP) and high-performance polymers.

As regulations evolve and industries demand higher performance, we can expect floor grating manufacturers to continue expanding their material choices and customization options, offering innovative solutions for new construction, retrofits, and specialized environments.

Design

Production Process

Floor grating grids are manufactured through various fabrication processes, each tailored to application requirements and material type. Common manufacturing techniques include:

- Welding: Welding is a favored technique for creating highly rigid and durable floor gratings. It involves the fusing of metal or fiberglass bearing bars using heat. Welding, along with riveting and swaging, is commonly employed in producing floor grates for platforms, trench grates, safety barriers, and elevated walkways.

- Metal Plate Expansion: This process slits and stretches metal sheets to specific sizes, creating a mesh with minimal material waste. Expanded metal grating offers excellent traction and is commonly used in catwalks, stair treads, and mezzanines.

- Metal Perforation: A punch or press is used to create precise hole patterns in metal sheets. Perforated metal grating is ideal for applications requiring drainage, ventilation, and slip resistance.

- Pultrusion: An automated method where resin-impregnated bars are pushed through a die, mainly used for fiberglass (FRP) grate production due to its consistent high-quality results and corrosion resistance.

- Molding: Materials are manually layered to the desired thickness before being placed in a mold to cure. This technique is typically used for making reusable plastic, composite, and FRP gratings.

- Hot-Dip Galvanization: After forming, metal gratings may be immersed in a bath of hot zinc oxide, strengthening them and enhancing resistance against oxidation and corrosion, especially in outdoor or chemical environments.

Materials

Floor grates are typically fabricated from robust metals such as iron, carbon steel, stainless steel, galvanized steel, or lightweight aluminum. Non-metallic materials are increasingly common, including reinforced plastic, composite polymers, and fiberglass-reinforced plastic (FRP). The choice of material depends on key properties such as load-bearing strength, flexibility, impact resistance, corrosion and abrasion resistance, and environmental compatibility (e.g., exposure to chemicals, moisture, or temperature extremes).

For those seeking chemical resistance or reduced weight, fiberglass grating and plastic grating are excellent alternatives to traditional metals, especially in wastewater treatment plants, commercial kitchens, and food processing facilities.

Considerations and Customization

Manufacturers offer extensive customization, producing floor gratings in various thicknesses, dimensions, load ratings, surface finishes, and patterns to suit different application requirements. When specifying floor grates, engineers consider factors such as:

- Required load capacity (light, medium, or heavy duty)

- Span, thickness, and bar spacing

- Drainage and open area percentage for water passage

- Slip resistance and surface texture

- Corrosion, chemical, and fire resistance

- Architectural aesthetics and pattern design (ovals, diamonds, squares, custom shapes)

- Compliance with regulatory standards (OSHA, ADA, ASTM, etc.)

Custom floor grating solutions are available for unique architectural features, high-traffic public spaces, and environments requiring specialized performance or branding.

Types of Floor Gratings

The floor grating industry offers a wide array of products, each tailored to specific use cases and performance requirements. Below are the most common types of floor gratings, along with their ideal applications:

- Heavy-Duty Gratings: Typically constructed with welded or pressure-locked bars, these gratings maintain their shape and structural integrity under high loads. They are ideal for industrial flooring, loading docks, manufacturing plants, and heavy equipment support.

- Trench Gratings: Also known as floor trough grates, these long, narrow gratings serve as drain covers in industrial settings, warehouses, food processing facilities, and city sidewalks. They provide walkable surfaces while allowing for effective drainage and easy access to underlying utilities.

- Stair Treads: Featuring cut-out holes with serrated or anti-slip edges, stair tread grates are designed to prevent slipping while allowing mud, water, and debris to drain through. They are essential for safe access in stairwells across commercial, industrial, and outdoor environments.

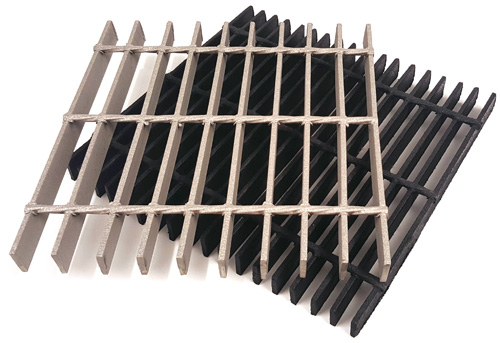

- Bar Grates: Bar gratings consist of parallel load-bearing bars and cross bars, machined together for maximum strength. Commonly used in mezzanine decks, walkways, catwalks, stair treads, and elevated platforms, they provide excellent load distribution and resilience.

- Metal Gratings: Manufactured from steel, stainless steel, or aluminum, these gratings are ideal for non-slip surfaces, surface filtration, and high-strength load-bearing applications. Steel grates offer superior strength and can be finished with coatings for enhanced corrosion resistance.

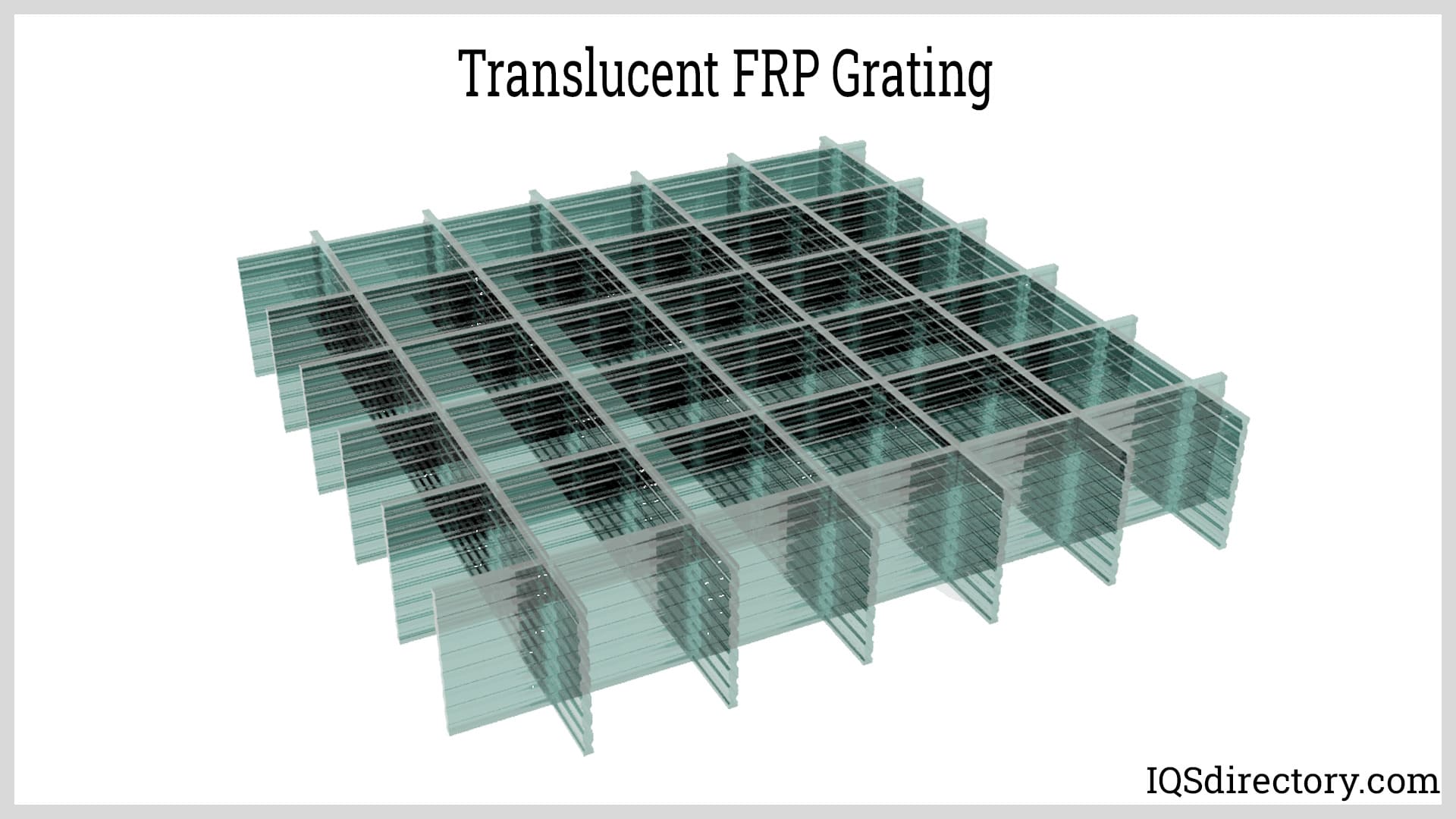

- Fiberglass Grates (FRP Grating): Fiberglass grates are lightweight, slip-resistant, non-conductive, and resistant to rust, corrosion, and fire. They are increasingly popular for wastewater plants, food processing, chemical handling, and marine environments where metal grating would corrode quickly.

- Plastic Grates: Plastic grates are lightweight, easy to install, rust-proof, and flame-retardant. They are suitable for food service, locker rooms, and corrosion-prone areas where hygiene and easy cleaning are priorities.

- Floor Drains: These specialized grates are engineered to efficiently remove standing water from floors, helping to prevent accidents and maintain sanitary conditions in commercial kitchens, bathrooms, showers, and industrial washdown areas.

- Architectural Grates: Available in metal or fiberglass, these gratings combine function with style, offering unique patterns and finishes to complement building designs while providing drainage, shade, or privacy screening.

Not sure which type of floor grating best fits your project? Ask an expert or request a sample to compare materials, load ratings, and surface finishes for your application!

Advantages of Floor Gratings

While objects such as floor vents, registers, and perforated floor tiles may serve similar purposes in facilitating air flow or drainage, floor grates offer distinct advantages that make them the preferred choice in demanding environments:

- Superior Load-Bearing Capacity: Engineered to handle heavy loads and continuous foot or vehicular traffic, floor grates maintain structural integrity in high-traffic industrial, commercial, and public spaces.

- Versatility and Adaptability: Floor gratings are available in a wide range of materials—including steel, aluminum, FRP, and plastic—and can be customized for specific applications, from decorative architectural features to heavy-duty drainage covers.

- Enhanced Drainage and Safety: Designed gaps in floor gratings channel water, oil, and debris away from walking surfaces, reducing slip and fall risks and maintaining a clean, dry environment—even in wet conditions.

- Corrosion and Chemical Resistance: Specialty coatings and materials such as stainless steel and fiberglass provide long-term durability in harsh, corrosive, or chemical-laden environments.

- Low Maintenance: Floor gratings are easy to clean and maintain, with open patterns that prevent debris accumulation and facilitate regular inspection and upkeep.

- Energy Efficiency: Gratings in raised floors, ventilation systems, and sunshades improve building energy efficiency by allowing airflow and natural light penetration where needed.

- Code Compliance: Floor grates can be specified to meet ADA (Americans with Disabilities Act) guidelines, slip-resistance standards, and OSHA safety requirements, supporting regulatory compliance in new construction and renovations.

In summary, the combination of durability, versatility, safety, and regulatory compliance makes floor grates the optimal solution for environments where performance and reliability are paramount.

Applications and Use Cases

Floor gratings are essential in a wide range of industries and environments. Common applications include:

- Industrial processing plants (chemical, food and beverage, wastewater treatment) for safe walkways, drainage, and spill containment

- Commercial buildings (shopping centers, office buildings, schools) for entryway drainage, ventilation, and architectural accents

- Public infrastructure (sidewalks, transit stations, parking garages) for stormwater management and pedestrian safety

- Marine and offshore facilities (docks, ship decks, oil rigs) requiring corrosion-resistant, non-slip surfaces

- Power plants and refineries for maintenance platforms, trench covers, and cable management

- Data centers (raised access floors) for optimal airflow and cooling efficiency

- Sports and recreation facilities (pools, gyms, locker rooms) for wet area drainage and slip prevention

- Residential settings (driveways, patios, basement floors) for water drainage and decorative effects

Looking for inspiration? Explore case studies or contact a floor grating expert for recommendations tailored to your industry or facility needs.

Accessories

Floor grate accessories are essential for the proper installation, security, and performance of floor grating systems. Here’s an overview of different accessories and their functions:

- Washers: Flat, thin discs with a central hole, washers distribute load and provide a smooth surface between the floor grate and bolts or fasteners, preventing damage and ensuring secure, even attachment.

- Bolts and Fasteners: These secure the floor grate to its frame or base. Available in various sizes and materials (stainless steel, galvanized steel, brass), the choice impacts the strength, corrosion resistance, and longevity of the installation.

- Locks: Used to prevent unauthorized access, especially for grates covering sensitive or hazardous areas. Locks may be integrated or added for enhanced security.

- Butterfly Clips, Hold Down Clips, and Hold Down Clamps: These keep the grate firmly in place, preventing movement or rattling during use. They are vital in environments with vibration, heavy foot traffic, or moving equipment.

- Channel Connectors: Join multiple floor grates to create continuous surfaces, accommodating thermal expansion and maintaining alignment in large installations.

When selecting floor grate accessories, consider factors such as material compatibility, installation environment (wet/dry, indoor/outdoor), load intensity, and safety or security requirements. Consult a knowledgeable supplier or structural engineer to ensure the chosen accessories are suitable for your specific application and meet all regulatory standards.

Accessories can be sourced from hardware stores, construction supply outlets, or specialized industrial distributors. Online retailers also offer a comprehensive selection. Always ensure accessories meet quality and load capacity requirements to ensure safe, reliable installation and long-term performance.

Installation

Proper installation is critical to the performance and safety of any floor grating system. Here are essential tips and best practices to guide your installation process:

- For bar gratings, position the cross rods on the top side to maximize load distribution and strength.

- Use a minimum of 1” bearings for bearing bars that are 2 ¼” or smaller. For bearing bars between 2 and 2 ½”, use 2” bearings to ensure stability and support.

- Make sure all clearances comply with the grating’s dimensional tolerances as specified by the manufacturer or relevant standards.

- When installing circular gratings, make cutouts for obstructions at least 2” larger than the obstructions themselves to maintain integrity and safety.

- Always follow the manufacturer’s recommended installation method and safety protocols, especially for elevated or load-bearing applications.

- Use proper fasteners and accessories to secure gratings in place, preventing movement and enhancing safety.

- Ensure grating is level and properly aligned to prevent tripping hazards and facilitate efficient drainage or airflow.

Need help with installation? Request installation guides or find certified floor grating installers for your region.

Proper Care and Maintenance of Floor Gratings

Maintaining floor gratings is essential for prolonging their lifespan, preserving performance, and ensuring safety. Here’s how to care for your floor grates:

- Regular Cleaning: Remove debris, dirt, and contaminants using brooms, pressure washers, or industrial cleaners. This prevents clogs that can obstruct drainage or airflow, especially in moist or high-traffic areas.

- Routine Inspections: Frequently check for damage, corrosion, or loose parts. Early detection allows for timely repairs, reducing risks of accidents or costly replacements.

- Protective Coatings: In harsh environments, apply or maintain protective coatings (e.g., galvanization or epoxy) to combat corrosion and wear.

- Secure Fastening: Use appropriate clips or clamps to prevent accidental displacement. Install locks in public or sensitive areas to deter unauthorized access.

- Immediate Repairs: Address any identified damage, rust, or instability without delay to maintain safety and structural integrity.

Neglecting maintenance can result in clogged grates, water pooling, unpleasant odors, reduced air quality, tripping hazards, or even collapse under heavy loads—leading to accidents, injuries, and operational disruptions. Proper maintenance, conversely, extends the useful life of your floor grates, keeps environments safer, and ensures optimal drainage and ventilation.

Want a maintenance checklist or best practices for your specific grating type? Download a care guide or schedule a maintenance assessment with a professional today.

Standards

Adherence to recognized standards is vital for ensuring the safety, quality, and regulatory compliance of floor grating systems in the United States and internationally. Key standards and organizations include:

- OSHA (Occupational Safety and Health Administration): Sets workplace safety regulations—including slip resistance, load capacity, and installation of floor gratings in industrial and commercial environments.

- ANSI (American National Standards Institute): Publishes consensus standards for product performance, materials, and installation of floor grating products.

- NAAMM (National Association of Architectural Metal Manufacturers): Provides detailed guidelines for the design, manufacture, and use of metal bar gratings, including recommended practices for load ratings and finishes.

- ASTM International: Develops standards related to material properties, corrosion resistance, fire ratings, and mechanical testing of grating materials.

Floor gratings are graded based on load-bearing capacity and construction, such as Heavy Duty (HD), Medium Duty (MD), and Light Duty (LD). Using gratings that don’t meet established standards can pose serious safety hazards, lead to structural failures, and increase liability or regulatory penalties. Non-compliant products may also deteriorate rapidly in harsh environments, increasing maintenance costs and downtime.

On the other hand, selecting floor gratings that meet proper standards ensures:

- Reliable safety for personnel and visitors

- Durability and quality for long-term performance

- Efficient drainage, ventilation, and load support

- Smoother project approvals and building code compliance

- Lower total cost of ownership and reduced need for repairs or replacements

For more information on codes and standards, or to verify compliance for your application, consult with a certified floor grating supplier or request technical documentation.

Decision Factors: How to Choose the Right Floor Grating

If you’re looking to purchase standard or custom floor grates, it’s crucial to collaborate with a skilled manufacturer who offers high-quality products and expert guidance. With the abundance of options available, consider the following decision factors to ensure you select the best floor grating solution for your needs:

- Application Requirements: Define the intended use (industrial, commercial, architectural, drainage, etc.), expected load, and environmental conditions (indoor/outdoor, exposure to chemicals, temperature, moisture).

- Material Selection: Choose from steel, stainless, aluminum, fiberglass (FRP), or plastic based on strength, corrosion resistance, weight, and cost.

- Compliance Standards: Ensure products meet OSHA, ADA, ASTM, or relevant local and federal regulations.

- Customization Needs: Determine if you need custom dimensions, patterns, finishes, or branding to fit unique project requirements.

- Budget and Lead Time: Establish project budget, timeline, and preferred delivery methods.

- Installation and Support: Assess the level of installation assistance needed—ranging from self-install kits to full-service contractor support.

- Maintenance Expectations: Factor in cleaning, inspection, and repair needs for long-term performance.

Ready to compare suppliers? Explore our curated list of leading floor grating manufacturers for trusted partners who can deliver on quality, compliance, and service.

Before reaching out, create a detailed specifications list to guide your search. As you review manufacturers, refer to your list to compare how their products and services align with your requirements. Select several suppliers, initiate conversations, and be thorough in discussing your application. Inquire about material options, load ratings, certifications, customization, lead times, and after-sales support.

A reputable manufacturer will appreciate your diligence, offering attentive customer service and tailored recommendations. After gathering information, compare your options to determine which provider delivers the best combination of quality, value, and support. Make your final decision based on this comprehensive evaluation.

Frequently Asked Questions About Floor Grating

- What is the best material for floor grating in corrosive environments?

Stainless steel and fiberglass (FRP) are recommended for high-corrosion areas such as food processing, wastewater, and chemical plants. - How do I determine the right load rating for my application?

Consult load tables and standards from manufacturers or industry bodies like NAAMM and ASTM, considering both static and dynamic loads. - Can floor gratings meet ADA (Americans with Disabilities Act) requirements?

Yes, ADA-compliant floor gratings feature limited opening sizes and slip-resistant surfaces to ensure accessibility and safety. - What maintenance is required for outdoor floor grates?

Regular cleaning, inspection for corrosion or damage, and timely repairs are essential. Use galvanized or stainless steel grates for maximum durability outdoors. - Are custom patterns and sizes available?

Most manufacturers offer custom fabrication to meet architectural, branding, or unique performance needs.

Have more questions? Contact a floor grating specialist or request a product catalog for detailed information.

Whether you’re specifying floor grating for new construction, retrofitting an existing facility, or upgrading safety features, choosing the right product is key to performance, compliance, and long-term value. Use the resources and guidance above to make an informed decision and ensure success for your next project.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services