Typically constructed from aluminum, steel or stainless steel, metal grates are popular for outdoor ramps and stairs, can be used to cover storm drains and sewers and in factory floors where it is necessary to keep the floor free of debris and liquids, or where a non-slip surface is required. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Strongwell is the world's leading pultruder of FRP structural components. Strongwell’s products include structural shapes, plate, fiberglass grating, building panels, handrail systems, ladder & cage systems, bridge decks, cooling tower components, planking systems, and custom shapes. If you would like more information about our company then please let us know!

Indiana is the benchmark other manufacturers strive to achieve. This financially strong, family owned company with over 35,000 sq. ft. of manufacturing area offers cost-effective, quality structural, decorative products, including precision crafted light & heavy duty welded gratings. Operating in accordance with NAAMM standards, Indiana has built its reputation on "personal service".

At Ryan Herco Flow Solutions, we take pride in delivering durable and reliable floor gratings designed to meet the highest standards of performance and safety. We understand the critical role that flooring systems play in industrial and commercial environments, and we engineer our floor gratings to provide strength, stability, and long-lasting value.

More Metal Grate Manufacturers

Metal Grates: Comprehensive Guide to Industrial Applications, Benefits, and Selection

Metal grates, also referred to as metal grating or industrial floor grates, are engineered grid structures that combine the robust strength of solid metal with the critical advantage of allowing light, liquid, air, and small debris to pass through. This unique design prevents unwanted and potentially hazardous accumulation on surfaces such as walkways, industrial floors, catwalks, and drainage covers, making metal grates a preferred choice for a vast range of commercial and industrial environments.

What Are Metal Grates?

Metal grates are fabricated panels or sheets, typically constructed from durable metals such as steel, stainless steel, aluminum, or galvanized steel. These materials provide essential properties such as corrosion resistance, high load-bearing capacity, and long-term durability, enabling metal grates to withstand demanding conditions in both indoor and outdoor settings.

Key characteristics of metal grating solutions include:

- Excellent strength-to-weight ratio

- Efficient drainage and ventilation

- Slip resistance and enhanced safety

- Customizable dimensions and configurations

- Compliance with OSHA and other safety standards

Metal grates find utility across numerous industries, serving as protective barriers, support structures, screening components, and safety platforms. They are especially vital in sectors where durability, hygiene, and safety are paramount.

Types of Metal Grates: Expanded Metal vs. Bar Grating

When choosing a metal grate product, understanding the primary types of metal grating is crucial. The two most widely used fabrication methods are expanded metal grating and bar grating, each offering unique properties and best-fit applications.

Expanded Metal Grating

Expanded metal grating is manufactured from a single solid metal plate that has been simultaneously slit and stretched, typically producing a diamond-shaped mesh pattern. This process results in a structurally sound panel with no welds or seams that could weaken over time.

- High strength-to-weight ratio: Expanded metal is lighter than solid metal sheets but still provides significant support and stability.

- Open mesh design: Permits optimal passage of air, light, water, and debris, making it ideal for walkways, stair treads, machine guards, and fencing.

- Cost efficiency: The expansion process minimizes waste, as virtually all of the original metal sheet is utilized.

- Non-slip surface: The textured mesh enhances grip, improving safety in wet or oily environments.

- Versatile materials: Available in carbon steel, stainless steel, and aluminum for a range of applications and resistance requirements.

Common search prompt: What are the advantages of expanded metal grating in industrial walkways and flooring?

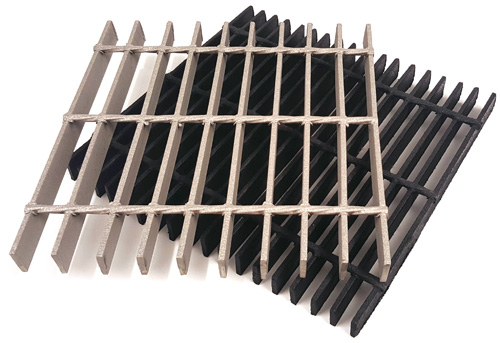

Bar Grating

Bar grating consists of parallel metal bars joined perpendicularly by crossbars, creating a rigid, open-grid structure. The bars can be assembled through various methods, including welding, swaging (mechanical fastening), pressure locking, or riveting, each offering different levels of strength and customization.

- Exceptional load-bearing capacity: Bar grating is frequently used in heavy-duty platforms, mezzanines, loading docks, and traffic-bearing surfaces.

- Rectangular and diamond configurations: While rectangular spacing is standard, diagonal bars or special patterns can offer additional support or aesthetic appeal.

- Material options: Choose from carbon steel, galvanized steel, stainless steel, and aluminum for corrosion resistance and durability in harsh environments.

- Custom fabrication: Bar spacing, thickness, and overall panel dimensions can be tailored to meet specific project requirements.

Action-driven prompt: Explore heavy-duty bar grating options for industrial flooring and structural support.

Material Selection: Which Metal Grate Is Right for Your Application?

The properties of your chosen metal grating material are critical to the success and longevity of your installation. Below is a comparison of common metal grate materials and their ideal applications:

- Carbon Steel Grating: Offers high strength and is cost-effective for most general industrial uses. Best for indoor or covered applications where corrosion is not a primary concern.

- Galvanized Steel Grating: Provides the strength of carbon steel with a zinc coating for enhanced corrosion resistance. Commonly used in exterior walkways, platforms, and drainage covers.

- Stainless Steel Grating: Superior corrosion, chemical, and heat resistance. Ideal for food processing, chemical plants, wastewater treatment, and marine environments. Explore stainless steel grate options.

- Aluminum Grating: Lightweight yet strong, with natural resistance to corrosion. Suitable for architectural applications, rooftop walkways, and areas where weight reduction is critical.

Search-style question: How do I choose between stainless steel, galvanized, and aluminum grating for my project?

Key Benefits of Metal Grates for Industrial and Commercial Use

Metal grates offer a range of benefits that make them indispensable in modern industry and architecture. Their design and material properties contribute to:

- Enhanced safety: Slip-resistant surfaces and efficient drainage minimize workplace hazards and accidents.

- Durability and longevity: Metal grating’s robust construction withstands heavy traffic, harsh chemicals, and extreme environments for years of reliable performance.

- Easy maintenance: Open mesh designs facilitate cleaning and prevent the buildup of debris or liquids that could cause corrosion or contamination.

- Versatility: Suitable for indoor and outdoor use, and customizable for virtually any application, from catwalks to trench covers and machine guards.

- Compliance: Metal grates comply with OSHA, ADA, and other safety regulations, ensuring access and safety in public and industrial spaces.

- Cost-effectiveness: Long service life and minimal maintenance requirements reduce total ownership costs.

Prompt for further user research: What safety standards should metal grating products comply with in your industry?

Primary Applications of Metal Grating Solutions

Metal grates play a pivotal role across a spectrum of industries, thanks to their blend of strength, durability, and functionality. Some of the most prevalent applications include:

- Industrial flooring and walkways: Provides safe, sturdy surfaces in factories, warehouses, and processing plants.

- Catwalks and mezzanines: Enables safe access to elevated equipment and storage areas.

- Drainage grates: Used in stormwater management, wastewater treatment, and floor drains to prevent flooding and debris accumulation.

- Stair treads and platforms: Offers slip resistance and structural support for staircases and access platforms.

- Machine guarding and safety barriers: Protects personnel from hazardous equipment while allowing visibility and ventilation.

- Architectural screening and facades: Enhances building aesthetics while providing sun shading and security.

- Trench covers and utility vaults: Secures underground utilities and allows for safe pedestrian and vehicular traffic.

- Marine and offshore platforms: Withstands corrosive saltwater environments and heavy loads common in oil rigs and shipyards.

- Food and beverage processing: Stainless steel grates ensure hygiene and easy cleaning in sanitary environments.

- Transportation infrastructure: Bridges, airports, and railways use metal grating for drainage, walkways, and safety barriers.

User research prompt: Looking for the best metal grating for your specific industry? Compare solutions for waste water treatment, food processing, marine, and architectural applications.

How to Select the Right Metal Grate: Factors to Consider

Choosing the optimal metal grating for your project involves evaluating several key decision factors:

- Load requirements: Determine the weight and type of traffic (pedestrian, vehicular, equipment) the grating must support.

- Environmental conditions: Assess exposure to moisture, chemicals, extreme temperatures, or corrosive substances.

- Grating type: Compare expanded metal versus bar grating for your application’s strength and design needs.

- Material selection: Choose between carbon steel, galvanized steel, stainless steel, or aluminum based on performance requirements and budget.

- Surface treatment: Consider options such as hot-dip galvanizing, painting, or powder coating for added protection and appearance.

- Compliance: Ensure the grating meets all relevant safety and accessibility standards, including ADA and OSHA.

- Customization: Evaluate availability of custom panel sizes, bar spacing, and edge banding to fit unique project specifications.

Prompt for further exploration: Need help determining the right grating for your facility? Request a custom quote or expert consultation based on your application and load requirements.

Comparing Metal Grates to Alternative Materials: Why Choose Metal?

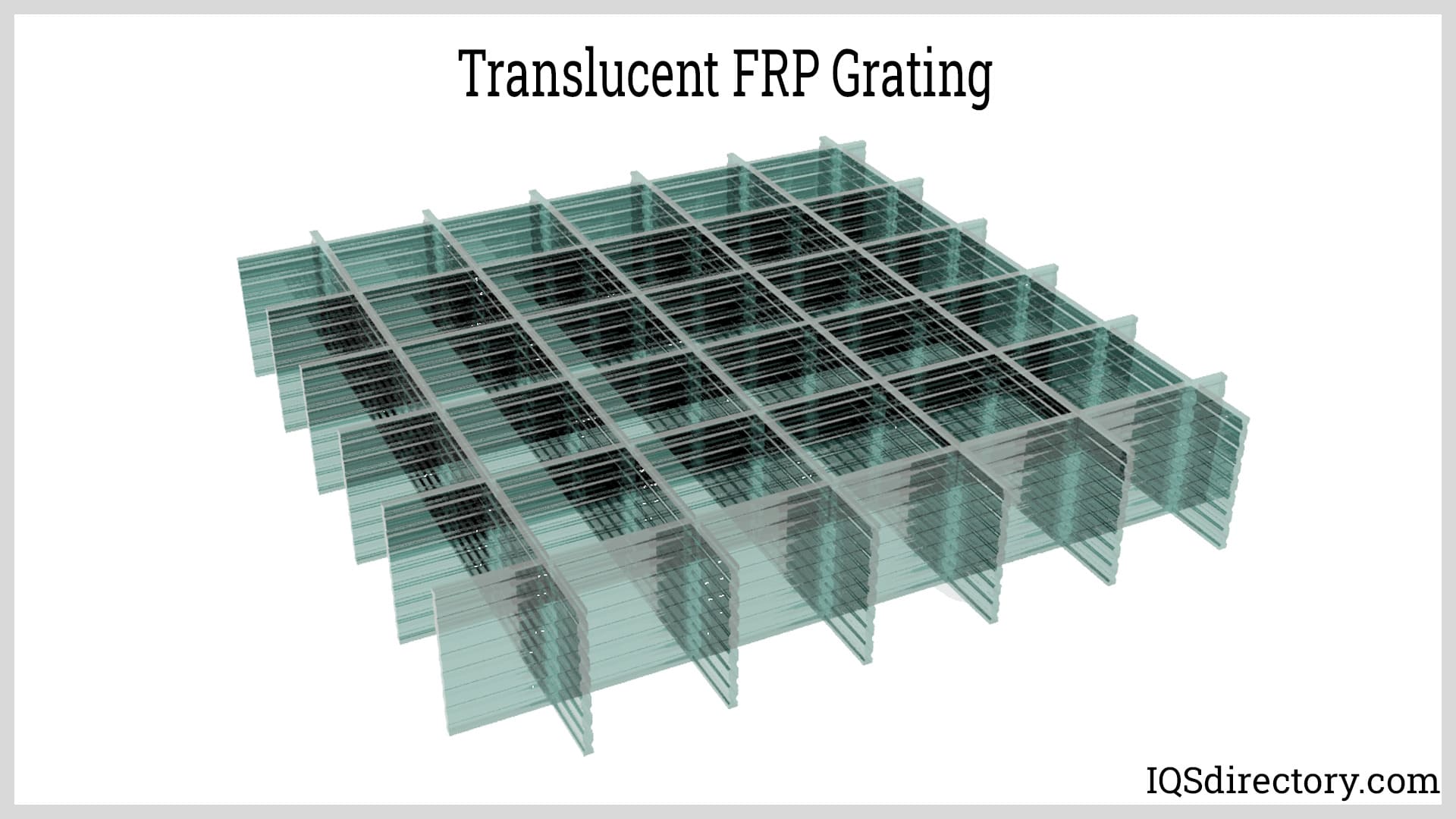

While fiberglass, plastic, and composite grating materials are also available, metal grates remain the industry standard for many demanding applications. Here’s why:

- Superior strength: Metal grates support heavier loads and endure more abuse than non-metallic options.

- Temperature and fire resistance: Metals withstand high heat and do not melt or burn like plastics or composites.

- Longer lifespan: With proper maintenance and surface treatment, metal grating can last decades in harsh environments.

- Electrical and thermal conductivity: Essential for certain industrial processes where grounding or heat transfer is required.

- Wider range of customization: Metal grates can be fabricated in virtually any size, shape, or design to suit architectural or functional needs.

Question-driven prompt: When should you specify metal grating over fiberglass or composite alternatives?

Installation and Maintenance Best Practices for Metal Grates

Proper installation and routine maintenance are essential to maximizing the safety, performance, and lifespan of metal grating products:

- Secure installation: Ensure grates are properly fastened and supported to prevent shifting or collapse under load.

- Surface treatment: Inspect and maintain protective coatings (galvanizing, paint, or powder coat) to prevent rust and corrosion.

- Regular cleaning: Remove debris, oil, and chemicals to maintain slip resistance and prevent buildup.

- Periodic inspection: Check for signs of wear, damage, or deformation, and replace or repair grates as needed.

- Compliance verification: Routinely confirm that installed grates meet industry standards and regulations for safety and accessibility.

Prompt for user action: Ready to upgrade your facility’s safety and efficiency? Learn more about professional installation and maintenance services for metal floor grating.

Custom Metal Grating Solutions: Tailoring Grates to Your Needs

Every facility and project is unique, requiring metal grating that matches specific structural, safety, and aesthetic criteria. Reputable metal grating manufacturers offer extensive customization options, including:

- Panel sizes, shapes, and thicknesses

- Bar spacing and orientation for load distribution

- Material grade and surface finish selection

- Edge banding and kick plates for safety

- Cutouts and notches for piping or equipment passage

- Custom color coatings and branding

Prompt for further search: How can custom-fabricated metal grates enhance the performance and appearance of your project?

Frequently Asked Questions About Metal Grates

- What is the difference between welded bar grating and expanded metal grating? Welded bar grating is constructed from load-bearing bars joined by welding, offering maximum strength for heavy-duty applications, whereas expanded metal is lighter and ideal for moderate loads and ventilation.

- Can metal grates be used in corrosive or marine environments? Yes, stainless steel and specially coated grates provide excellent resistance to chemicals and saltwater, making them suitable for marine, wastewater, and chemical processing industries.

- Are metal grates ADA compliant? Many metal grating products are designed to meet ADA standards for accessibility, with closely spaced bars to support wheelchairs and foot traffic safely.

- How do I maintain metal grates for optimal performance? Regular cleaning, inspection, and maintenance of protective coatings are recommended to ensure long-term safety and performance.

- Where can I buy high-quality metal grates? Leading manufacturers and distributors offer standard and custom metal grating solutions. Find stainless steel grating suppliers here.

Conclusion: Why Metal Grates Are the Smart Choice for Industrial Applications

Metal grates are an essential component in modern industrial and commercial infrastructure, delivering unmatched strength, durability, and safety where it matters most. Their versatile design, extensive material options, and customizable features ensure that there’s a metal grating solution for every project—whether you’re upgrading a warehouse floor, designing architectural screening, or specifying safety barriers for a marine platform.

By selecting the right type, material, and configuration, you can maximize the return on your investment in metal grating, ensuring years of reliable, low-maintenance performance. For expert guidance, product comparisons, or custom quotes, connect with a trusted metal grating manufacturer or supplier today.

Prompt for next steps: Need help specifying or sourcing the ideal metal grate for your application? Contact industry experts for personalized recommendations and pricing.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services